3D CAD, Dye Sublimation Printers, and the 1.6 Trillion Dollar Fashion Industry. Part 3 of 3

This is part 3 of 3 in our series on Digital Pattern Flattening.

- 3D CAD in the apparel and fashion segment seems to be on everyone’s lips.

- Dye sublimation printers are to apparel, what 3D printers are to mechanical goods.

- These two trends combined with advanced 3D to 2D flattening have the potential to be a driving force in the deployment of digital solutions in the textiles market.

What is needed to make this a reality? A killer app of course. Fortunately one already exists. Read on to learn more.

What is the problem?

Fast moving consumer markets have unique problems. These include accurately predicting consumer tastes or trends, addressing seasonal, geographic, and cultural considerations, accounting for retailer requirement variations and then forecasting and producing the volume of product required to meet the business needs.

The problem is it is extremely difficult to get it all right. Typically production volume is overestimated which leads to excess inventory at retail and that leads to deep discounting of the unsold inventory.

The other problem is underestimating consumer demand which leads to full price sales but lack of inventory reduces potential revenue.

Consumers and retailers are increasingly pushing for more and more variation and unique product which reduces the economies manufacturing large productions lots.

The 3D CAD - 3D Printing Paradigm Applied to the 1.6 Trillion Dollar Fashion and Apparel Market

The dye sublimation printer allows manufactures to meet the customization needs of of consumers and retailers and better manage the inventory volume needs of manufactures. It offers:

- Rapid response to consumer demand

- The ability to adapt to market trends or material cost changes

- Lower and in some cases negligible cost variation testing

- Profitable unit-of-1 manufacturing

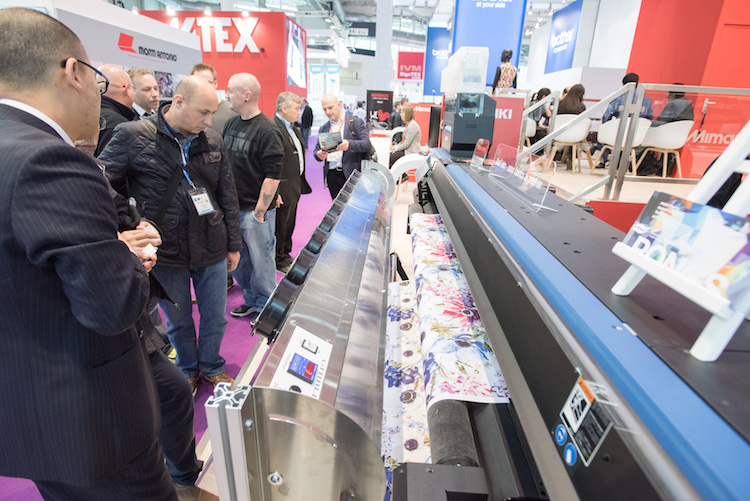

Dye Sublimation printers print graphics on fabrics. They are available from many different manufacturers including HP, Roland, Canon, Epson, and Mimaki.

According to Ronald van den Broek, the European General Manager for Mimaki, speaking at the FESPA 2017 show in Hamburg, “...there is growing demand for shorter run and customised textile products. The printers are also being used for sampling, speeding time to market without breaking the bank.”

This is why the presence of dye sublimation printing may dramatically shape the use of 3D CAD in fashion design going forward. In fact we would be even more bold and call this an AutoCAD moment.

What is an AutoCAD moment?

It is the moment you realize the viability of the old way of doing business is on an irreversible downward trend. That means if we continue to use historical tools and practices we are most certainly going lose business and later be put out of business. We called this an AutoCAD moment owing the transformative effect ushered in by AutoCAD shortly after it was introduced.

The KIller App. Transforms Apparel Design

One of the barriers holding up the widespread adoption of dye sublimation is the digital patterning workflow that offers similar advances in going from 3D digital designs to 2D flat patterns. For regular readers, you know this problem has been solved. (Read Part 1 and Part 2 off this series)

What you might not know is that this very same 3D to 2D flattening technology can also flatten graphics that have been texture mapped to the 3D surfaces. Here is quick video example

The technology has been in use for many years in, for example, the automotive industry. In those instances it has been used for detailed textures applied to 3D surfaces like the dashboard in your car.

The Graphic Mapping Workflow For Dye Sublimation Printing and Manufacturing

Lets apply this example to a design for a dress. Suppose we want to respond quickly to a retailer request related to a dress which is currently in the retailer channel. The dress is selling well, but so are other products that have a zebra print. The retailer asks you to make a version of the dress with a zebra print to see if it would sell as well as predicted.

Here is the original dress that was modeled using Rhino 3D.

Here are the steps that were taken:

- Find a suitable graphic, or texture and map it onto the 3D model

- Simplify the 3D model to a small number of pieces(10 or less is ideal). This will make the sewing faster and easier

- Flatten the pieces into a collection of 2D pattern pieces

- Check the alignment of the print/graphic

- Render the final pattern pieces for printing on the dye sublimation printer

All this can be done in less than 30 minutes.

The video shows an example of this process using Rhino 3D and ExactFlat Armadillo for the graphic and pattern flattening.

Summary

Dye Sublimation Printers present new opportunities for bringing apparel products to market.

When combined with 3D CAD digital design, and 3D to 2D digital patterning, these opportunities reach their full potential and offer immediate benefits:

- Rapid response to consumer demand

- The ability to adapt to market trends or material cost changes

- Lower and in some cases negligible cost variation testing

- Profitable unit-of-1 manufacturing

3D to 2D patterning and graphic flattening is the bridge that connects digital design and automated production. Since this problem has been solved it remains to be seen how fast the leading 3D CAD companies create tools that further increase the productivity of apparel design. It is a 1,6 trillion dollars world wide industry, first movers will likely enjoy a handsome reward.

If you want to know more about Digital Patterning, click the link below and book time to talk to an expert.

If you want to try digital patterning for yourself. Click the link below to request a free trial.