What's the Business Case for the Transition to Digital? - Part I

Fashion and Textiles Market Growth Insight

Business Goal - Dramatically increase company value by:

refining the use of under performing assets (ex. idle manufacturing equipment)

adding additional capabilities with exponential growth potential

Business Problem - No clear path to growth

unable to wring additional profit out of current automation efforts

lack the tools needs to automate in new areas (i.e. pattern making, sewing, assembly, etc...)

Why do Fashion and Textiles Manufacturers need 3D CAD and Digital Patterning?

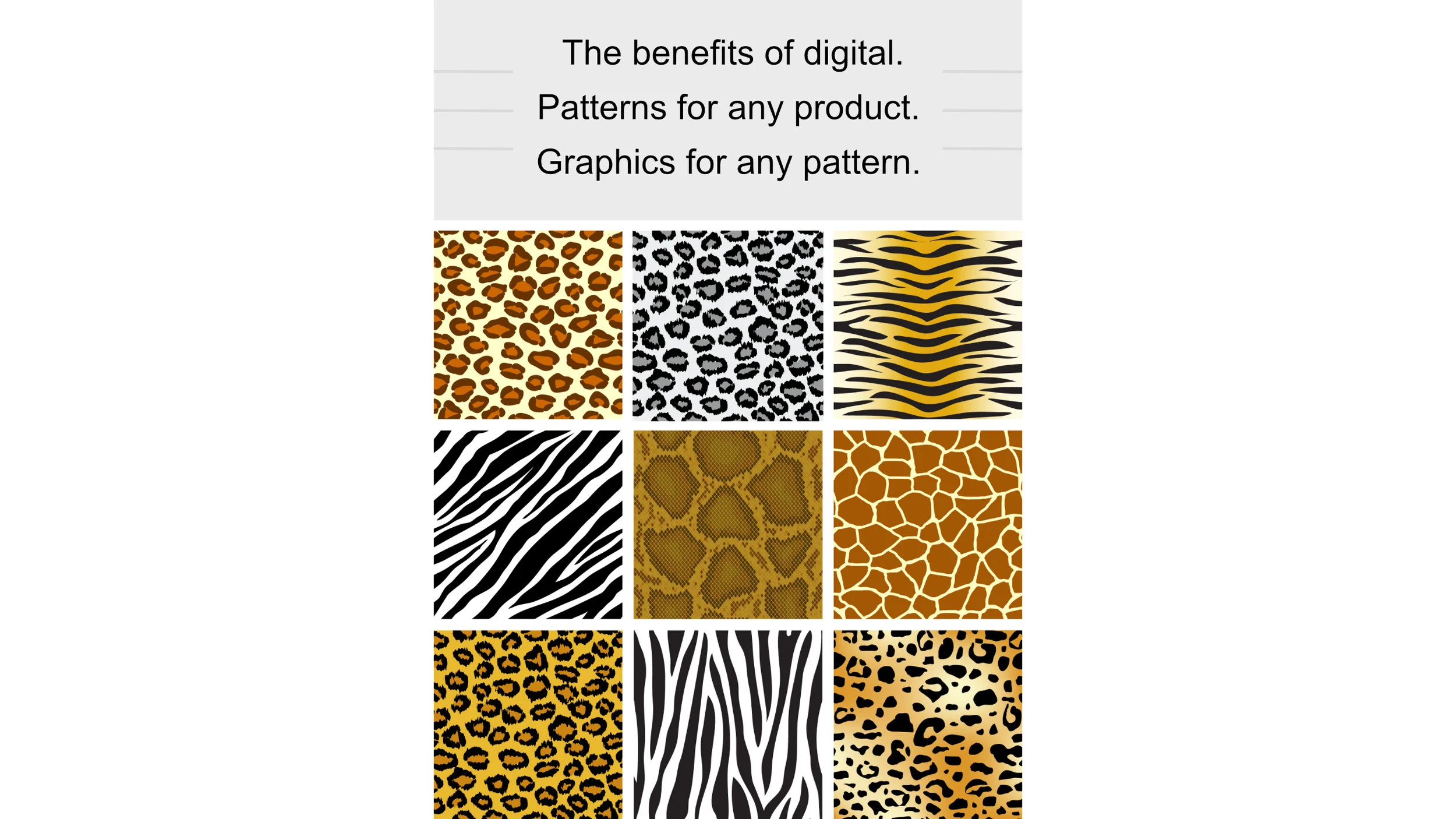

3D CAD, or computer-aided design, is the use of computer technology for design modeling and documentation. Creation of 3D CAD models is the first step when replacing manual 2D pattern making with an automated process. It is a well established fact that manual processes consume profit. Over the past 35 years the switch to CAD has been the primary method for companies in the discrete manufacturing space to increase profit through automation.

The immediate growth areas for 3D CAD are in the world of industrial fabrics and composites where manual tasks dominate the design and production-prep workflow. Legacy manual processes are slower, often by a factor of 10 compared to their digitally automated alternatives. While the 3D CAD and digital patterning solutions needed to address this issue are readily available, they are only now being implemented in companies in these segments.

Why partner with ExactFlat?

ExactFlat helps manufacturers automate and in many cases ends manual processes by optimizing processes and eliminating the barriers to success. Key examples include:

Reusing previous design software and cutting tool investments

ExactFlat digital patterning software works with the 3D CAD and cutting tools that you already own. That means no need to rip out and replace what's working. That also means reduced training and start-up time for your staff and no dip in productivity. Making the transition truly lets you get more done with what you have today.

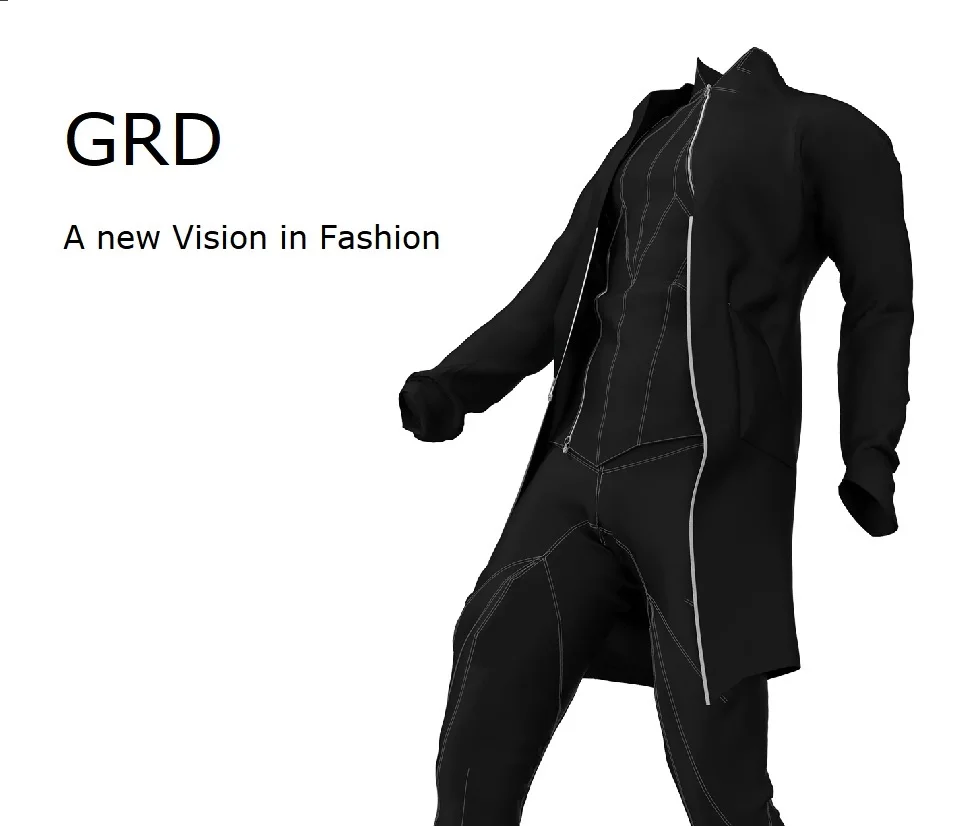

Eliminating physical prototypes and fit testing.

Building prototypes, creating sample patterns, cutting and sewing samples, and building fit test models add days if not weeks to the process. Digital patterning leverages the material data included in your 3D CAD model to simulate the exact performance of the fabric. And strain and sag analysis displays help you identify and correct any issues before you cut.The result is perfect patterns in minutes.

Utilizing financing options to reduce the upfront costs.

ExactFlat has partnered with Centra Funding LLC to help smaller clients get started fast. The process couldn’t be any easier or more straight forward. Sign up for the program, implement the software, and pay as you increase profitability.

How do you know this is right for your organization?

If you are looking for ways to increase profitability of your business, click the link below and schedule time to meet with one of our experts. The team at ExactFlat will review your business needs and current tools and then give you recommendations on how to create patterns and products faster, and with lower overall costs.