Fast Flexible Furniture Design and Manufacturing - Part II

Utilizing the MicroFactory for Furniture Manufacturing

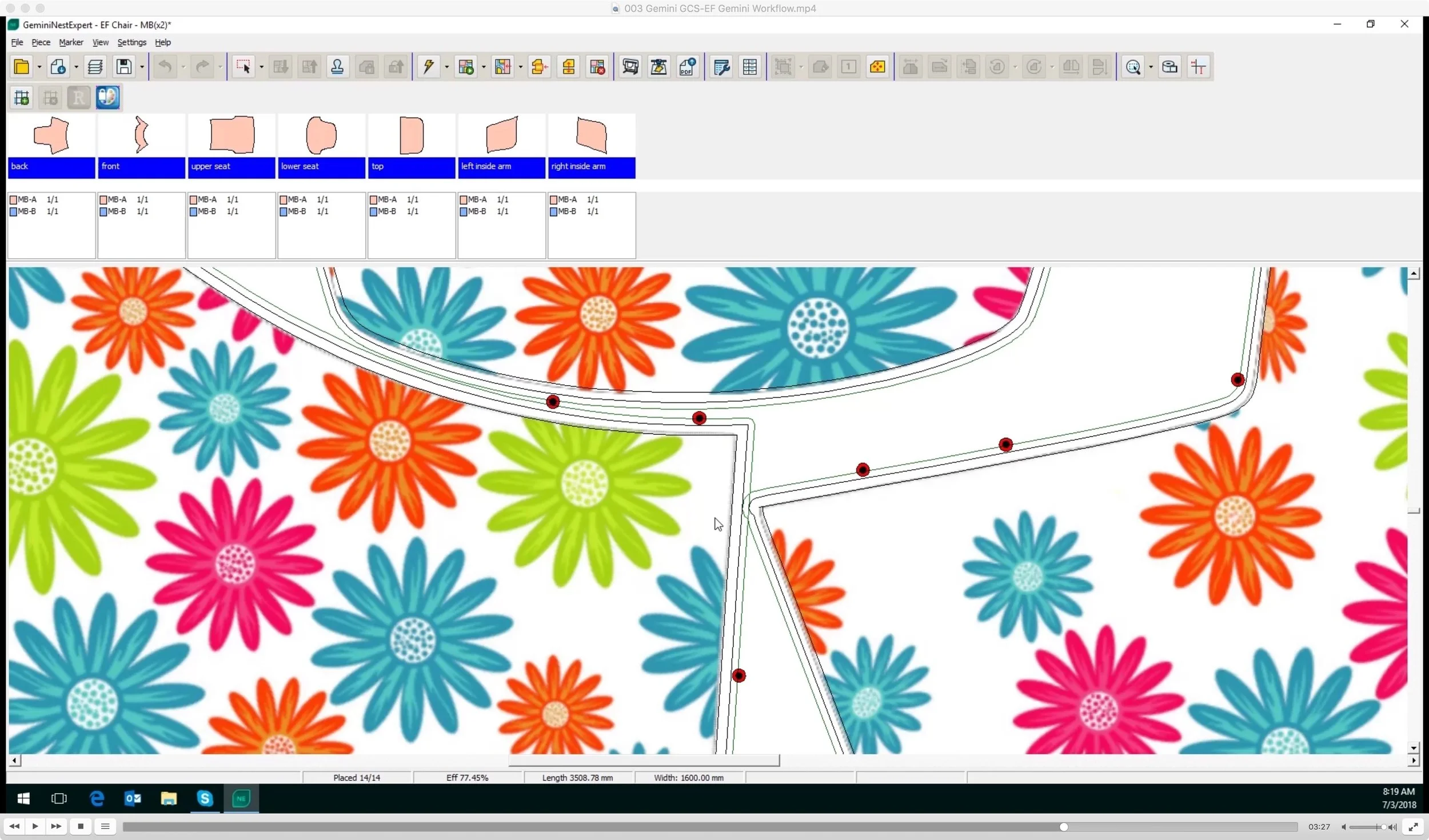

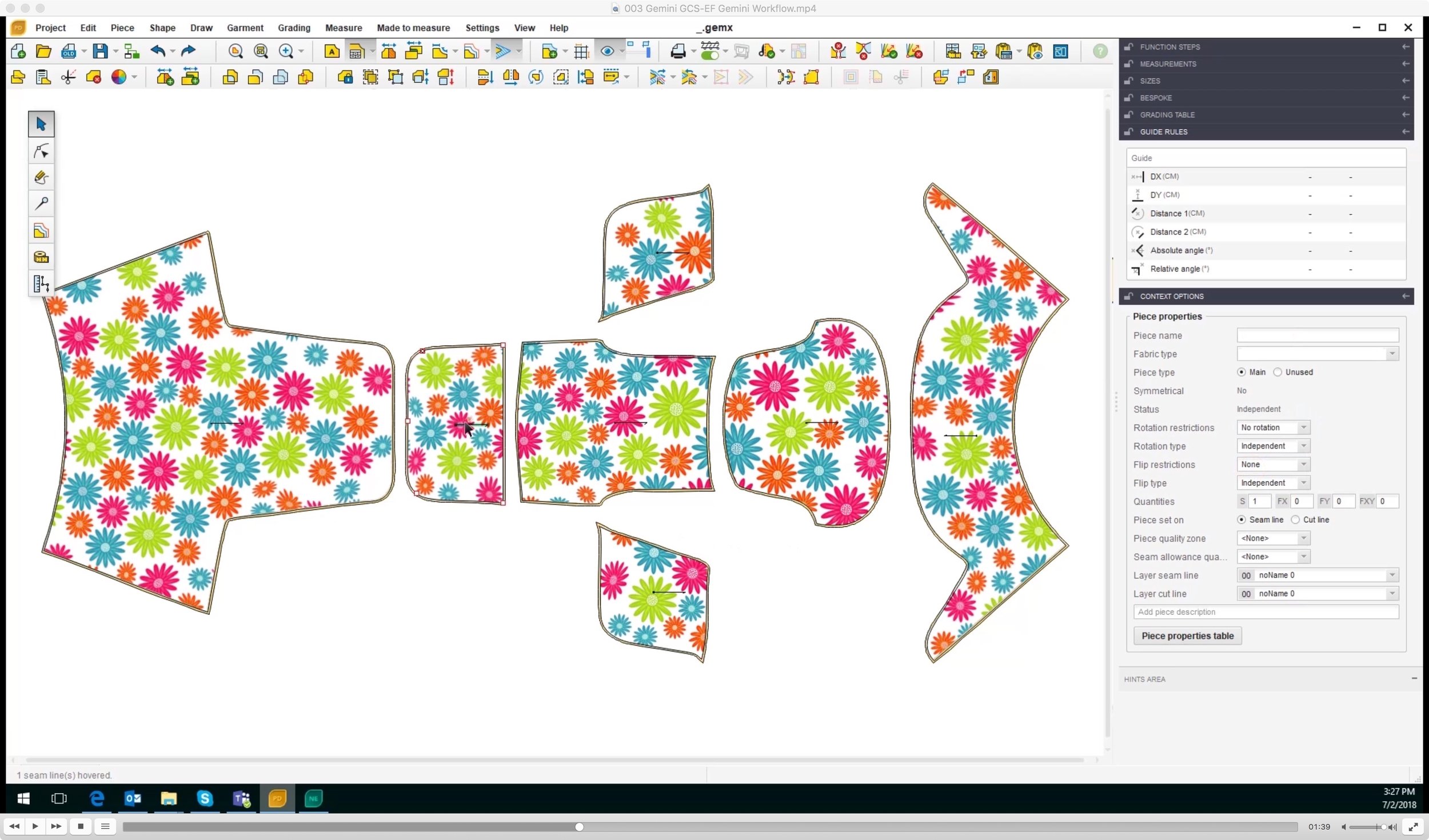

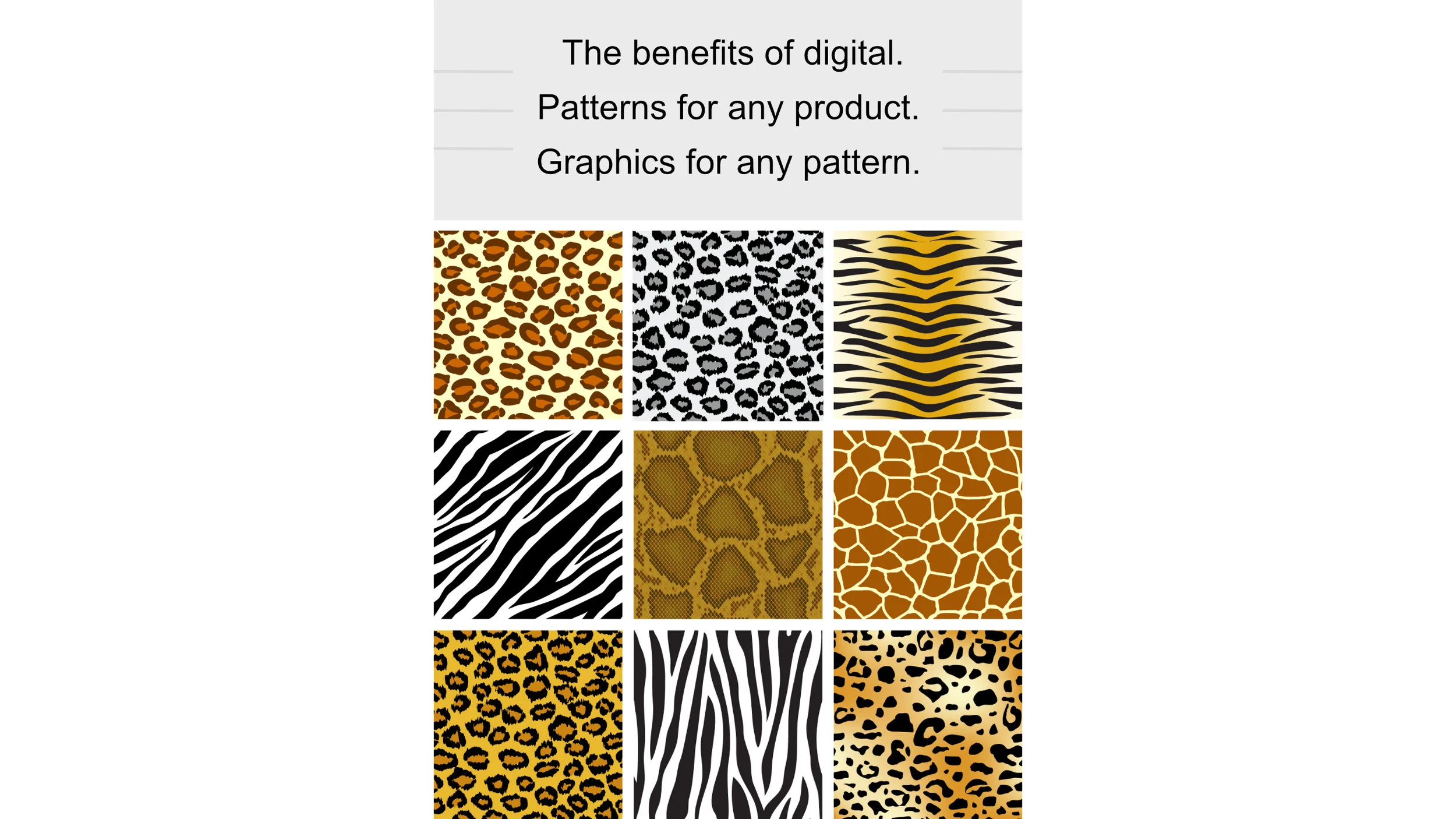

Digital Patterning makes it easy to reduce or eliminate the manual steps typically associated with 2D pattern making. And the recently introduced ExactFlat Monarch software system adds the ability to apply texture mapped graphics directly to the pattern with perfect flow matching. The challenge now is to utilize that data to print and cut perfectly aligned pattern pieces which are ready for assembly.

Digital Patterning and Production Showcase

To review, the automated process includes 5 basic stages:

- Design using 3D CAD

- Graphic Texture Mapping and 3D to 2D Flattening

- Pattern Engineering and Materials Cost Optimization

- Printing and Cutting

- Sewing and Assembly

In many cases each stage is done by a different team and perhaps at a different facility. With the transition to digital, one Master Model is used to collect and co-ordinate all of the data needed to complete and optimize the entire process.

The team at ExactFlat, working with their industry partners Gemini CAD Systems and Nextwave recently completed an end-to-end showcase of the process using the sample furniture model shown here.

After the Pattern Engineering and Material Cost Optimization stage was completed, the print file was delivered electronically to the Nextwave Microfactory for production. The Tech Pack components provided to the Nextwave team include Cut lines, Seams, Notches and the flattened graphics. All data is aligned and integrated into one file ready for printing and cutting. Changes to the master model can be updated in the tech pack in minutes.

With all of the information in one file, changes to the master model can be updated in the tech pack in minutes.

Simplifying Production with the Textiles MicroFactory

A Microfactory is an integrated solution for printing, setting, cutting and in some cases sewing of textiles. The key advantages of this component of the digital process is that the microfactory

- consumes the digital pattern and texture file directly with little or no intervention

- enables the use of any type of graphics since the pattern is printed during production

- provides several additional ways to reduce waste (in this case, ink waste and cleaning cycles)

The Nextwave solution utilizes large-format printing, involving water-based dye sublimation printing technology. This minimizes waste as well as allowing manufacturers to recover as much as 95% of the ink typically lost during cleaning. Next is the setting process which adheres and bonds the ink to the fabric ensuring uniform colors across the entire production run. Cutting is also automated with little or no manual intervention. The printed and set fabric rolls are loaded onto a feeder system at the cutter. Camera systems recognize the cutting points, the cutter path is optimized, and a top-quality cut is produced for each piece.

Meet with the Experts

To learn more about how your business can utilize digital patterning and production tools to address your on-demand product needs, click on the link below. You'll be able to schedule a time to meet with one of our experts to discuss the best solution for your team.