Patterns in minutes - Athletic Shoes

3D design and digital patterning tools help reduce the time it takes to create production-ready patterns that fit. In this example, we'll walk through the process of converting a typical athletic shoe concepts into patterns that are ready to cut with just a few minutes of effort.

Step 1. Develop the 3D Design.

Working with a digital last or 3D shoe template allows anyone on the team, even designers who are new to 3D CAD, to quickly create or explore a variety of designs concepts. With 3D designers can:

- revolve the model to inspect the design details from any angle.

- made edits or explore "what if" scenarios and see the impact immediately.

- generate a rending of the model and get a feel for the final look of the shoe.

The shoe last model provides a perfect starting point for the design process. With 3D anyone on the team can visualize and edit the model in real-time.

Step 2 - Prepare the model for Flattening

In many cases the "faces" of the CAD model don't line up with the cut lines planned for production. Piece Creation is the process of cutting or combining 3D CAD faces into 3D pieces that are ready for flattening.

Using a 3D model in this step provides designers with another tool to control the final design. The cut lines defined during the piece creation stage are typically used to specify the seam or joining locations. This process helps ensure that the precise instructions for the shoes fabrication are included as part of the model rather than just as notes or "suggestions" sent to the manufacturer.

Digital Patterning software allows designers to specify exactly where they want seams and cut lines to appear in the model. Fashion brands can now develop a "3D tech pack" that includes all of the details in a single file.

Step 3 - Generate the Pattern in Minutes

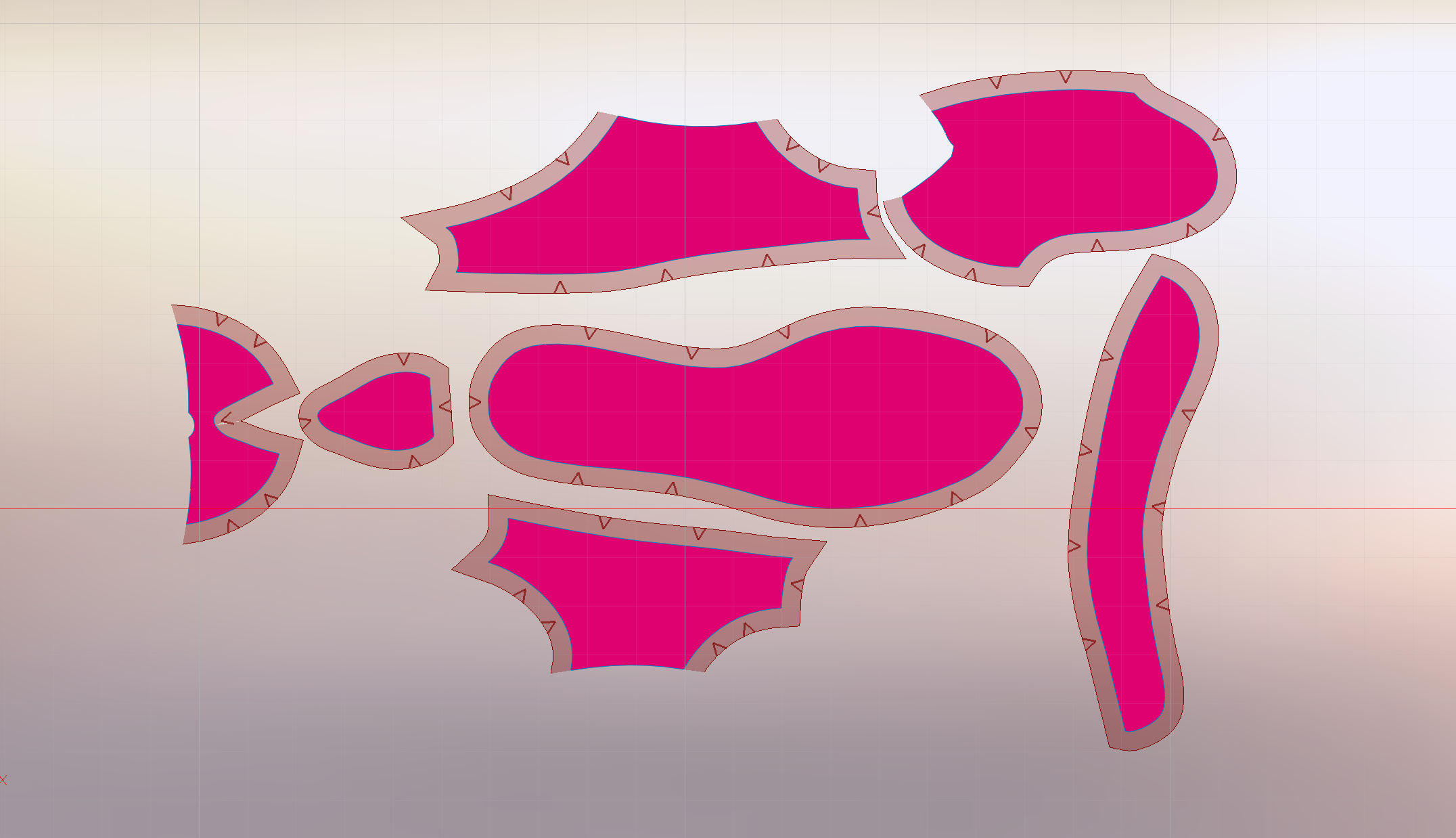

Once the design is complete and the 3D model has been prepared for flattening, its a simple process to convert the 3D pieces into 2D patterns using digital patterning software.

Converting the 3D model into 2D patterns happens in a matter of minutes. The strain and sag display helps save time by identifying possible production or fit problems before any material is cut or sewn.

Step 4 - Add Pattern Details then cut and assemble

After the 3D model has been converted to 2D pattern pieces, pattern details such as seams, notches, piece tags for eyelets, and material specifications can be added with a few mouse clicks. At this point the design now includes all of the information needed to produce the final product. And all of the documentation from the 3D virtual model to the 2D production drawings are all linked together. Changes in one place are immediately reflected everywhere.

And that's it. Create perfect patterns that are ready to cut in just a few minutes. If you'd like to validate the benefits of 3D design and digital patterning on your business just click on the link below and schedule a time to speak with an expert.

Meet with the experts at Texprocess 2018

Mark Jewell (CTO) and Eaton Donald (CEO) of ExactFlat will be at Texprocess 2018, the industry trade event focused on the effective implementation of technology. Click on the link below to schedule a time to meet and discuss ways that ExactFlat can help your business with your automation initiatives.