Enabling Cost-effective use of Composite Materials in Aircraft Design

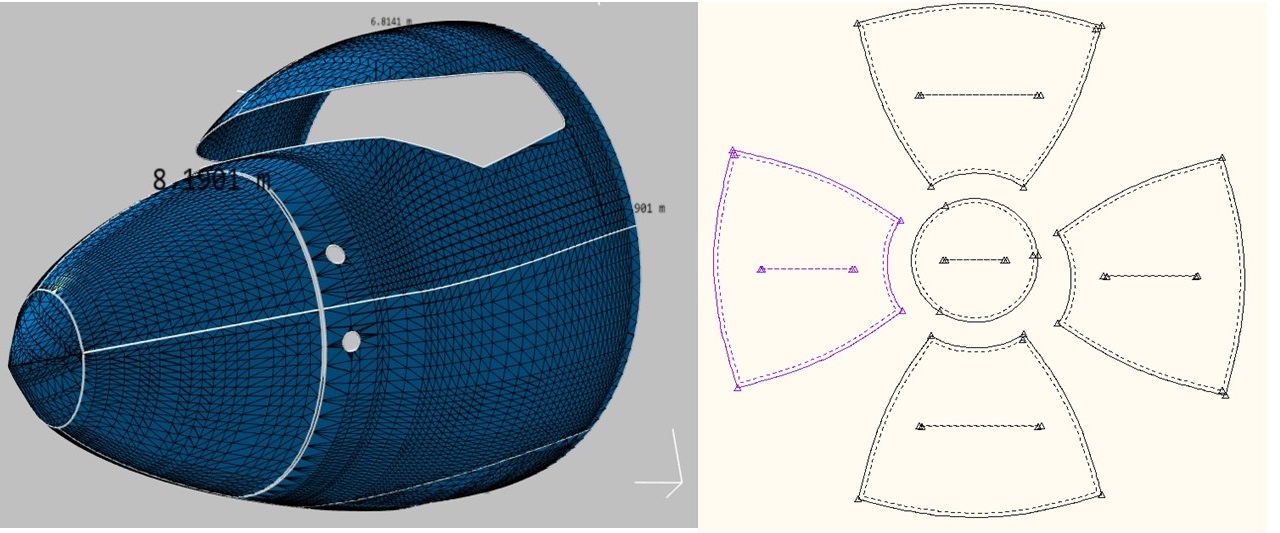

Composite materials are ideal for aircraft components allowing structures like the forward radar dome assembly to incorporate features for aerodynamic performance while providing strength and light weight .

The use of composite materials has become common, if not required in aircraft design. When Boeing rolled out its new 787 Dreamliner in 2012, it boasted that the aircraft was 50 percent composite material. New aircraft rolling off the line today almost all incorporate some type of composite material into their designs.

The strength to weight advantages as well as the opportunity to consolidate components, to precisely control part loading and to innovate shapes to address capacity, and other performance concerns are primary incentives for their use.

Conversely, cost of materials and manufacturing methods post the key drawback to employing these composites more broadly. Digital patterning and production automation technologies provide a simple way for aircraft manufacturers to address these challenges.

How does Digital Patterning help?

Understanding precisely how the 2D sheets of composite material (patterns) will layout in the 3D mold during the manufacturing process and eventually in the final parts is critical. In many cases, this key aspect of the process is done manually with several trial and error steps. This leads to the increase development cost with working with composite materials.

Digital Patterning software such as ExactFlat are used to automate this portion of the process, remove the “guesswork” and drive down costs.

Working with accurate materials information

In the first step, the material type and properties are selected from the library or specified directly by the designer. The software uses this information to calculate strain and displacement/movement of the material as it transitions from 3D to 2D.

Simulating precise composite material flattening behavior

Due to the anisotropic nature of a typical woven composites, automation software solutions provide several ways to completely describe the material prior to final pattern definition. In the case of ExactFlat, this function is addressed using the Bias Flatten tool. After the grain line direction is defined, this tool is used to specify key characteristics of the material including fiber strength and spacing.

Converting the 3D design into 2D patterns in minutes

The next step in this portion of the process is to review the pieces for strain and sag. The understanding gained at this step is a critical time saver. Areas showing strain will fray the material or not form at all.

With Digital Patterning software like ExactFlat and Gerber AccuMark, designers can work seamlessly between the 3D design and the 2D pattern. This enables the entire team to explore performance and producability issues quickly, collaboratively and without the need for extensive physical prototyping. Click on the image to see the process in action.

Determining where and how to introduce strain relief (i.e. darts)

Another important consideration beyond the flattening algorithms include a simple method for creating darts for contouring and strain relief. The strain display in ExactFlat is used to indicate areas of high and low or negative strain in the 2D pattern and associated part as a result of the flattening process. With this information, designers can define dart location and size needed to ensure the best possible design.

The fewer dart used, the better, as they disrupt fiber continuity and load paths. Darts are cut so that when the material is dropped into the mold, the material can conform to the tool without excessive deformation. In addition, dart patterns need to be staggered, so darts in multiple layers are as far from each other as possible and don’t overlap. With legacy patterning methods, these considerations are addressed after expensive composite materials are cut and molded. With digital patterning, dart definition is completed early in the process where it has the least impact on costs.

Trim or “Salvage” equals wasted material. Defining trim on-the-fly or solely in the production stage can lead to excessive material usage and clean up. Digital Patterning helps alleviate this issue.

Allowing for Trim Material

Any useful patterning software for composite design should allow the user to extend the edge of the pattern out beyond the edge of the part. This allows for some sacrificial material to be trimmed from the finished laminate. Often a scribe line is etched into a tool to show where the part needs to be trimmed, or a composite trim jig is made to scribe the part.

Once the 2D pieces are defined along with darts and trim material, pattern piece nesting is done. Nesting refers to the process of laying out cutting patterns to minimize the raw material waste.

Learn More

Digital Patterning can reduce the time it takes to create the pattern pieces used in the pre. In our next article we’ll review the other pre-production advantages of digital patterning. To learn more, click on the link below and set up a time to speak with one of our experts.