Top 3 reasons why patterning is transitioning from manual to digital

Why change your process?

Business growth, or even continued competitiveness and profitability, almost always requires some type of process change. For pattern makers, the transition or change to digital is the only practical solution for process improvement.

Many of our clients have asked us to help them validate the advantages prior to making the transition. With their help we’ve been able to put together the Top 3 Reasons why manual pattern making processes are transitioning to digital.

Reason #1: The benefits of increased Speed and Output

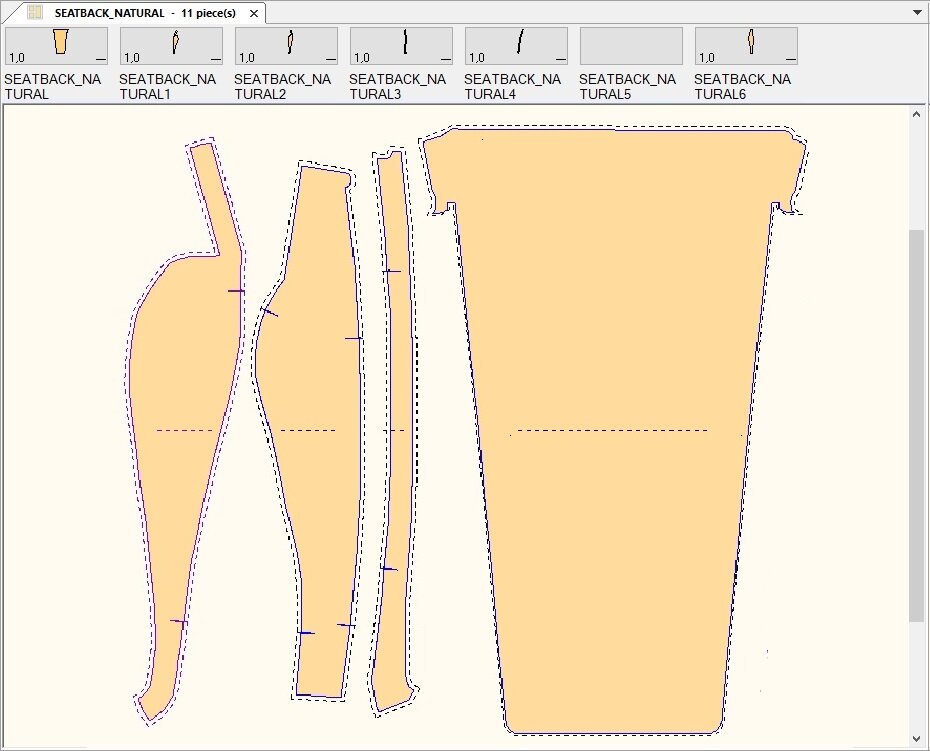

Manual pattern making is a slow and labor-intensive process. Determining the proper pattern piece size and shape can consume hours if not days of effort. With Digital Patterning, 3D CAD or Scan models are converted into 2D pattern pieces in a matter of minutes. And with the additional time savings, manufacturers using digital are producing roughly 3 times as many patterns with the same staff.

Reason #2: The need for First Time accuracy

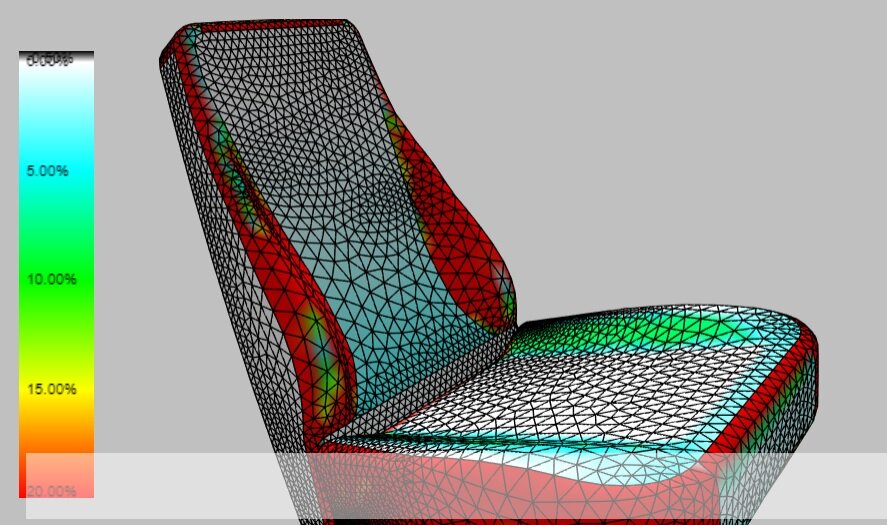

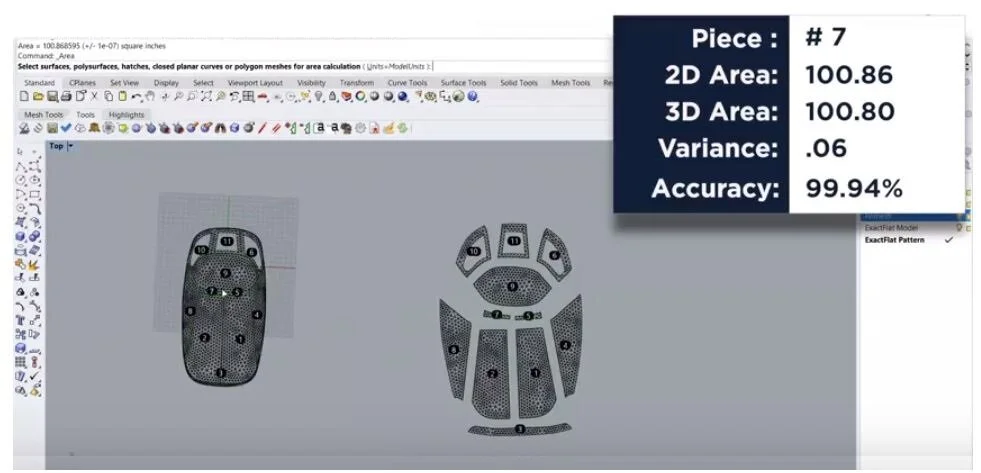

Fit testing and several rounds of pattern reworking is common when using the manual patterning method. This repetitive and non-value-added phase of the process is virtually eliminated with digital patterning.

Digital Patterning software solutions like ExactFlat utilize advanced algorithms and actual material properties data to simulate the exact unfolding behavior of fabric. This, combined with strain and sag displays, helps pattern makers ensure a perfect pattern and fit before any materials are cut or sewn.

Simplify the process, eliminate steps, save time, and reduce cost. Go from part or prototype, to CAD, to fit simulation, and then to pattern seamlessly, within a single, integrated 3D environment.

Reason #3: The Opportunity to Simplify the Process

A manual pattern making process typically requires several tasks and may involve multiple skilled resources. Steps from design to production may include:

Physical prototype model making,

Taping and draping sample materials over the prototype,

Pinning, marking and cutting the patterns

Digitizing the pattern samples for editing in other software tools.

All of this before executing the repetitive cutting, sewing, and rework steps described above.

The digital pattern process avoids these steps by working directly from the 3D model and then converting that model into 2D patterns. The other steps are by-passed. And modern Digital Patterning tools integrate with the design software and cutting equipment you already own. So implementation and managing of the environment is also simplified.

Let the Experts Help your business implement the change to digital patterning

If you’re trying to decide what solutions to choose, and how to make the transition to digital patterning, why not contact the experts. Simply click on the link below to schedule a session with the team from ExactFlat. They’ll help you discover the path to tripling your patterning output in no time.