How to Pick the Right 3D to 2D Flattening Software

Making the move to digital patterning

Digital patterning closes the automation gap between design and manufacturing. It provides a simple and cost-effective way to increase pattern making throughput by 3x to 16x. Digital patterning software products, like the suite of solutions from ExactFlat, are as varied as the companies that use them.

In this article, we’ll provide a simple guide to help you identify, evaluate, and ultimately implement the solution that’s right for your business.

Guideline # 1 – Must work with your 3D CAD package

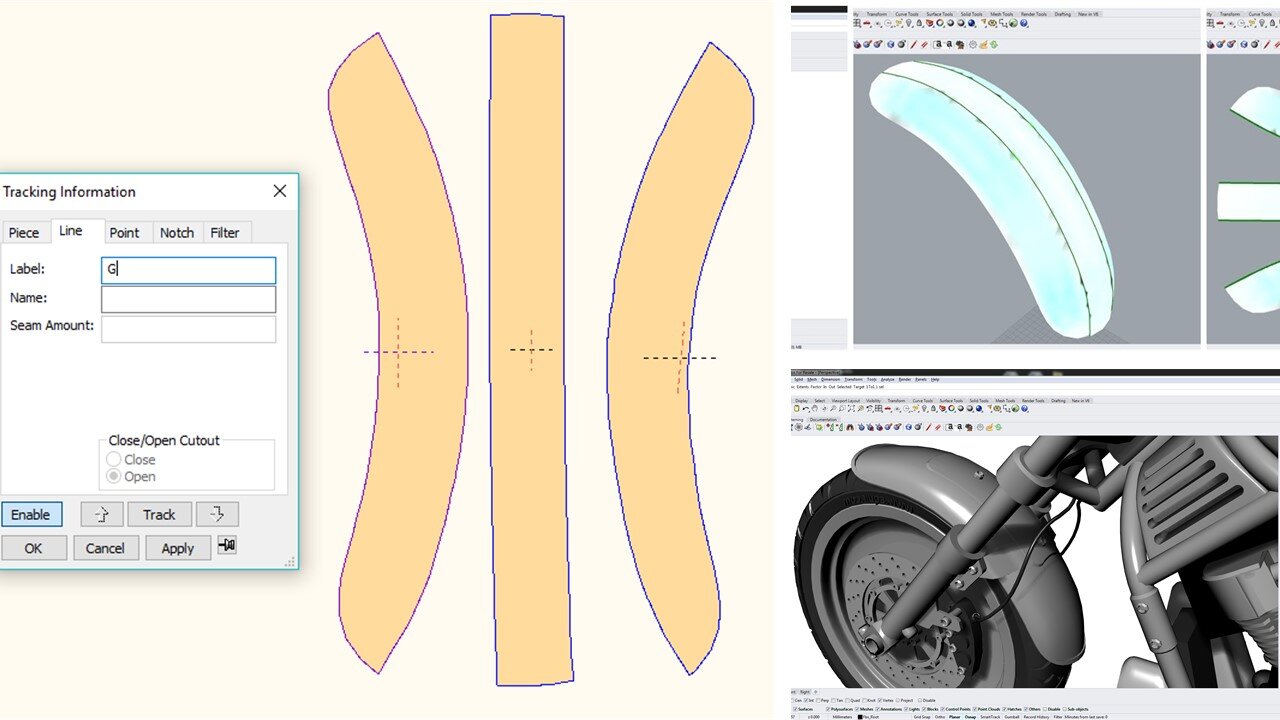

The first place to start is by assessing your current or planned 3D CAD needs. The 3D CAD model is the foundation for an end-to-end digital process. Product designs are created or 3D scanned into the CAD tool and then cut into 3D pieces. The pieces are then opened directly within the digital patterning systems and converted from 3D designs into 2D patterns in minutes. ExactFlat works with any modern 3D CAD tool using plugins(optimal) or remote services on the Cloud.

Most popular – ExactFlat for Rhino 3D

If your business is new to 3D, consider Rhino 3D and ExactFlat for Rhino 3D. The design tools are simple to use and the integration with ExactFlat for Rhino 3D is completely seamless. In addition, the licensing models for both applications (i.e. standalone, network, software code or hardware dongle.) are identical.

Guideline #2 – Must include the flattening and patterning tools for your industry

All ExactFlat solutions include the same 3D to 2D flattening features. But since each type of manufacturing process mandates slightly different patterning tools, additional capabilities are also required. To help address this, ExactFlat offers unique packaging options, each purpose-built to meets specific business requirements. For example:

Working with woven carbon fiber Composites? Pick CompositeFlat.

Integrating custom graphics on your parts? Consider ExactFlat Monarch.

Interested in optimizing materials using nesting? Choose ExactFlat for SOLIDWORKS.

Best Value – ExactFlat for SOLIDWORKS

Many manufacturers already use SOLIDWORKS to design and validate the performance of the “hard” components in their products. By adding ExactFlat for SOLIDWORK to the solution stack, companies integrate all parts of the product. This streamlines the entire process with very little incremental expense.

Guideline #3 – Must integrate with your Textile Printers and Automated Cutters

The final step in closing the gap is to deliver the graphics and patterns in a format that is usable by your textile printers and cutters. The ideal production process requires little to no editing or re-creating of the pattern data.

Best Choice – ExactFlat

All ExactFlat solutions export standard DXF (drawings, markers) and Tiff (aligned graphics) file formats. These formats are supported by every major textile printer and cutter manufacturer. This means you do not need to make changes or re-engineer your production environment to take advantage of digital patterning.

Learn More

As you can see, selecting the right digital patterning tool your business is straightforward. But it always helps to get advice you can trust. To learn more about the process or to get started now, just click on the link below. You’ll be able to schedule a time with one of our experts to discuss how the transition to digital patterning can help your business