Case Study: Carbon Marine Builds Composite Boats 60% Faster with ExactFlat

Case Study: Carbon Marine Builds Composite Boats 60% Faster with ExactFlat

Context

To drastically reduce production times and costs, Carbon Marine, a pioneer in designing and manufacturing full-carbon powerboats, transitioned to digital patterning using ExactFlat. They estimate this change has shortened their production cycle from approximately three months to just three weeks.

According to Production Manager Drew Davidson, “Using ExactFlat, alongside a few other major process changes, made a huge difference. Our results and time savings were way better than expected. As we continue working digitally, we’re going to become even more efficient. I believe we can get the whole process down to about two and a half weeks.”

Challenge

Going from a three-month to a three-week production cycle was a significant goal. Carbon Marine needed to rely on innovative tools that seamlessly integrated into their existing production workflow.

Solution

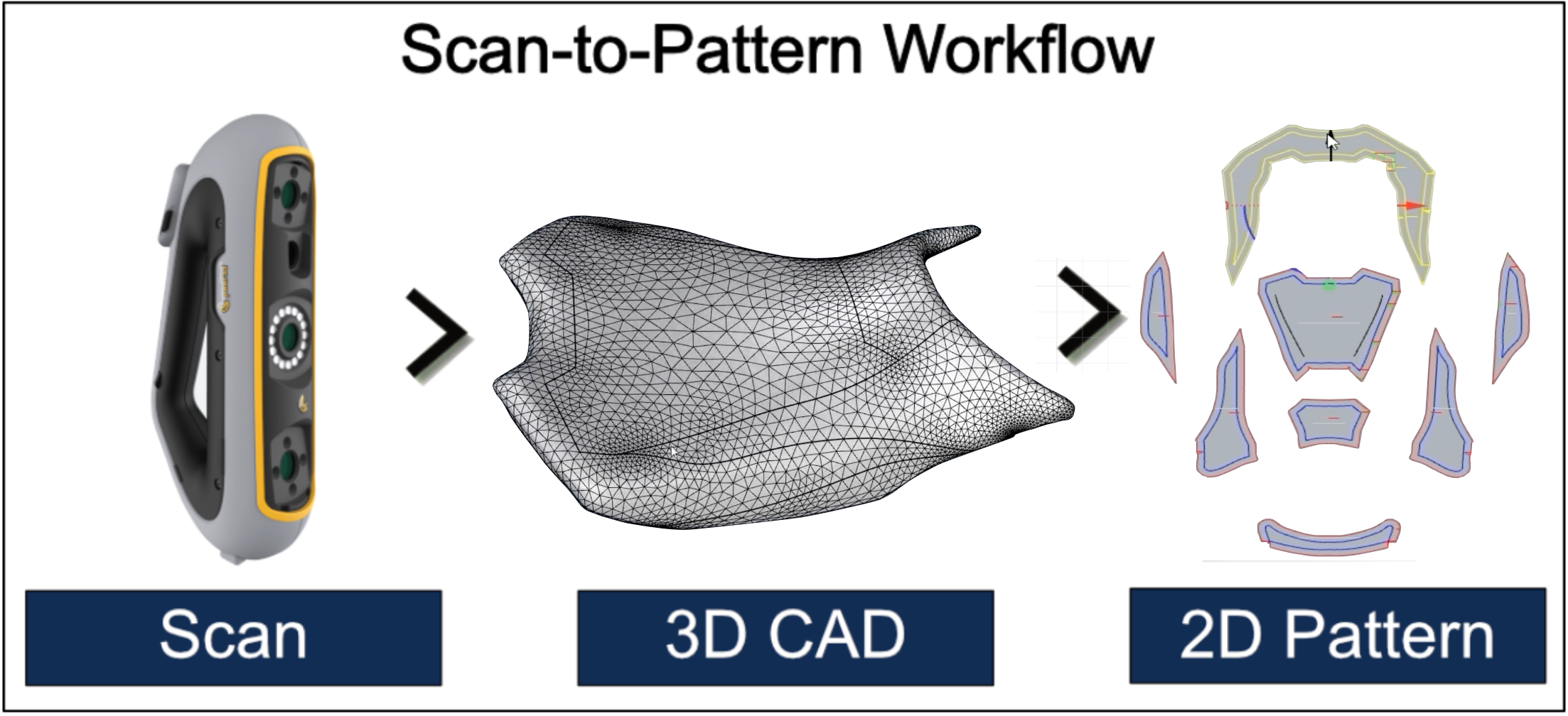

The team at Carbon Marine utilized the software and integration services from the experts at ExactFlat. The new tools easily fit into their design and production steps, which included:

Step 1: Creating a Digital 3D Model of the Design Concept

The process starts at the design stage. While there are various ways to create the 3D design model (e.g., editing existing templates or converting 2D sketches using CAD), in this case, the team started with a physical prototype or plug for the boat.

A 3D scanning tool, similar to Peel 3D, captured the details of the design as a surface model. The model was sent to a 3D artist to add elements like the deck, windshield, and internal components. Once complete, the design model was ready for virtual fit testing, interference checking, and client visualization.

Step 2: Preparing the 3D Model for Flattening

In the past, generating the 2D pattern pieces manually was the longest and most tedious stage. Drew Davidson noted that this changed when Carbon Marine adopted ExactFlat.

“Getting the patterns, ply layup, and fiber orientation correct is incredibly important. That’s where the strength comes from. It’s also the most time-consuming part of the job. Before ExactFlat, we would spend weeks working out rough patterns, trimming, and adjusting to avoid wrinkles or gaps.”

Now, with ExactFlat, they can convert the 3D design into 2D pattern pieces in minutes. The process includes:

Accessing the 3D model and hiding surfaces or components not to be flattened.

Creating a finite element mesh of the surfaces.

Cutting and combining surfaces into 3D pieces.

Generating offset surfaces for individual ply layers.

Step 3: Flattening the 3D Design into 2D Pattern Pieces and Plys

“While this used to be the most challenging part of the process, it’s now the easiest step with ExactFlat,” Davidson said.

Using ExactFlat, the team assigns material properties and grain direction to the 3D pieces. The software then unfolds the pieces into 2D patterns, ensuring precision with advanced algorithms and bias metric tools that simulate actual material behavior.

Accuracy and confidence are key advantages of the digital process. “Confidence is crucial,” Davidson explained. “We build the boats using pattern templates. When you're dealing with large, expensive material pieces, you can't afford to make mistakes.”

Results

By integrating ExactFlat into their workflow, Carbon Marine was able to achieve a 60% reduction in production time and significant cost savings. The digital patterning process was fully operational in less than 30 days.

Is It Time for Your Business to Consider Digital Patterning?

Carbon Marine closed the automation gap between design and production with ExactFlat and is seeing impressive results after just one project. Want to learn how digital patterning can benefit your business? Contact us today to schedule a time to speak with one of our experts.

Contact

www.exactflat.com | Sales@exactflat.com