Adding texture without adding production costs – Part II

The transition to digital closes the automation gap

In the first article in this series we reviewed the value of adding surface texture to molded plastics and stamped leather parts. We also explored the challenges for creating texture using manual methods including:

- Limiting surface finish options to a select group of swatches.

- Physically transferring the patterns to the mold.

- Manually reworking the mold until the parts and finish are right.

Digital patterning software solutions like ExactFlat Monarch eliminate the manual steps and areas for errors. Closing this automation gap saves costs as well as increases the flexibility and design options.

Apply the texture on the 3D part

With digital patterning, digital versions of the texture (image shown on the left above) are applied directly to the 3D CAD model (image on the right). This allows for multiple variations of the pattern to be viewed, edited and approved prior to any production steps.

Convert the 3D design into 2D pattern plates

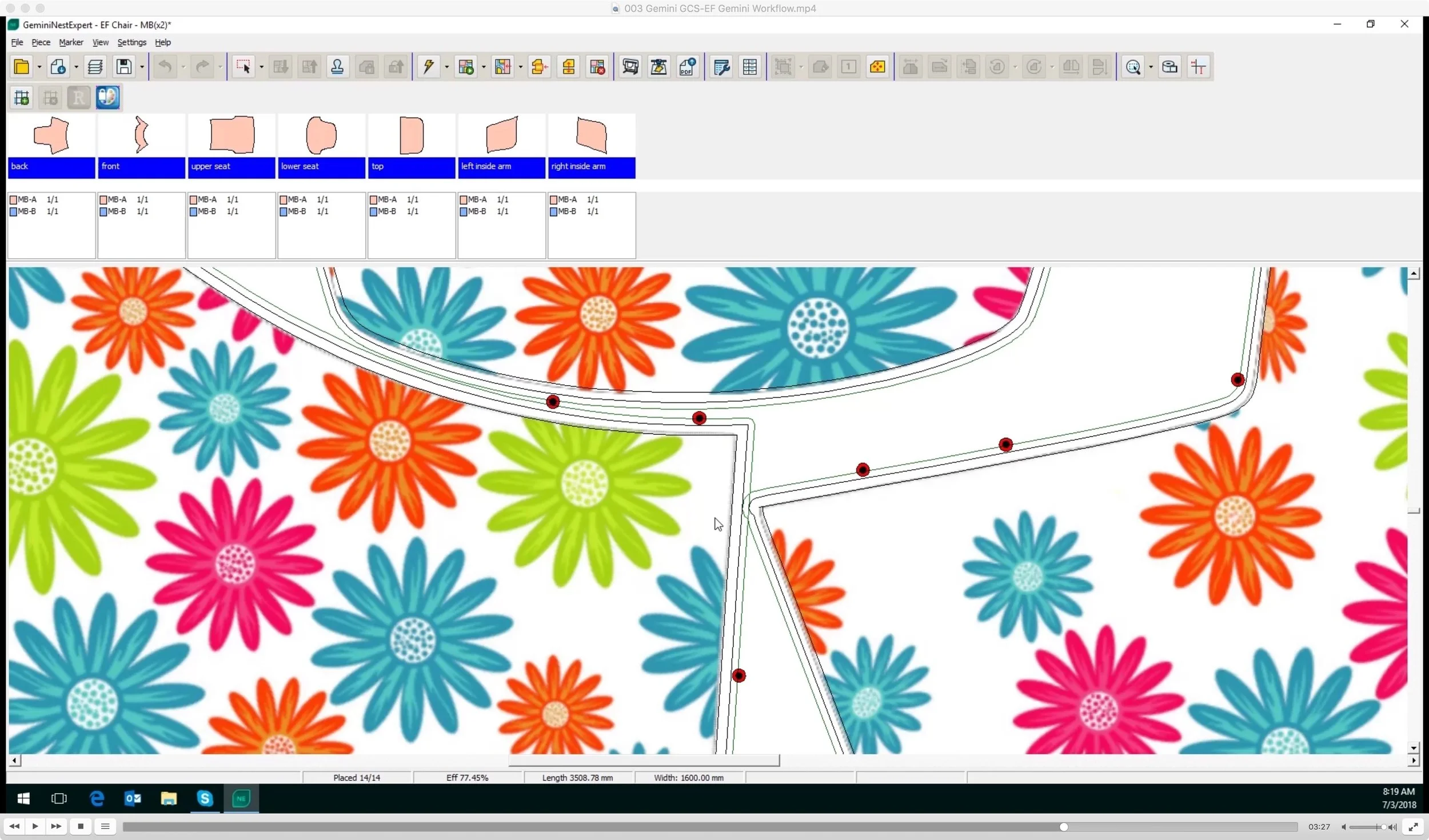

Once the texture is selected and rendered, the 3D model is converted directly into the 2D pattern plates used in the manufacturing process. ExactFlat Monarch provides several time saving features to accelerate the process.

- Powerful flattening algorithms which “tweak” the graphics as needed to eliminate pattern distortion (i.e. pinch or stretch) in the mold.

- Alignment and rendering features used to ensure accurate graphics placement regardless of the size or number of pattern plates needed for the mold.

The entire process is completed in minutes rather than the hours or days commonly associated with manual processes.

With manual methods, transition areas like the complex curve section highlighted here can introduce surface finish problems. Digital Patterning tools save time by accounting for and addressing these issues automatically.

Transfer the finish pattern directly to production

At this point the materials produced include the pattern layout (cut edge) as well as perfectly aligned graphics. These digital assets are immediately ready for use in the mold etching or multi-axis milling process. No additional manual correction is needed.

Once the texture swatch has been applied to the 3D model, the conversion to highly accurate, production-ready 2D patterns and print files occurs in minutes.

Learn More

Finish is often a critical factor in product selection. The process of texturing a mold for plastics and stamped leather goods can be accelerated by the implementation of digital patterning best practices.

If you’re in the parts manufacturing business, or if you’re a consumer product designer looking to use surface finish to increase aesthetic appeal, we can help. Just sign up to speak with one of our experts and explore the benefits of the transition to digital.

Other reference articles on the topic of the mold texturing process

Investing in the right process in order to get the right finish

https://www.starrapid.com/blog/making-and-measuring-surface-textures-in-injection-molding/

Adding texture to a 3D CAD design

https://blogs.solidworks.com/tech/2018/11/solidworks-2019-favorite-feature-3d-texture.html