What's keeping Fashion Brands from transitioning to the benefits of digital? - Part I

3D design, digital patterning and automated printing/cutting provide the easiest path for reduced production cycles and improved profitability. So why are some Fashion Brands still trusting their businesses to outdated 2D methods? In this article we'll try to explore a few of the false beliefs that may be keeping business leaders from transitioning to the benefits of digital design and production.

The software can't really capture our design intent.

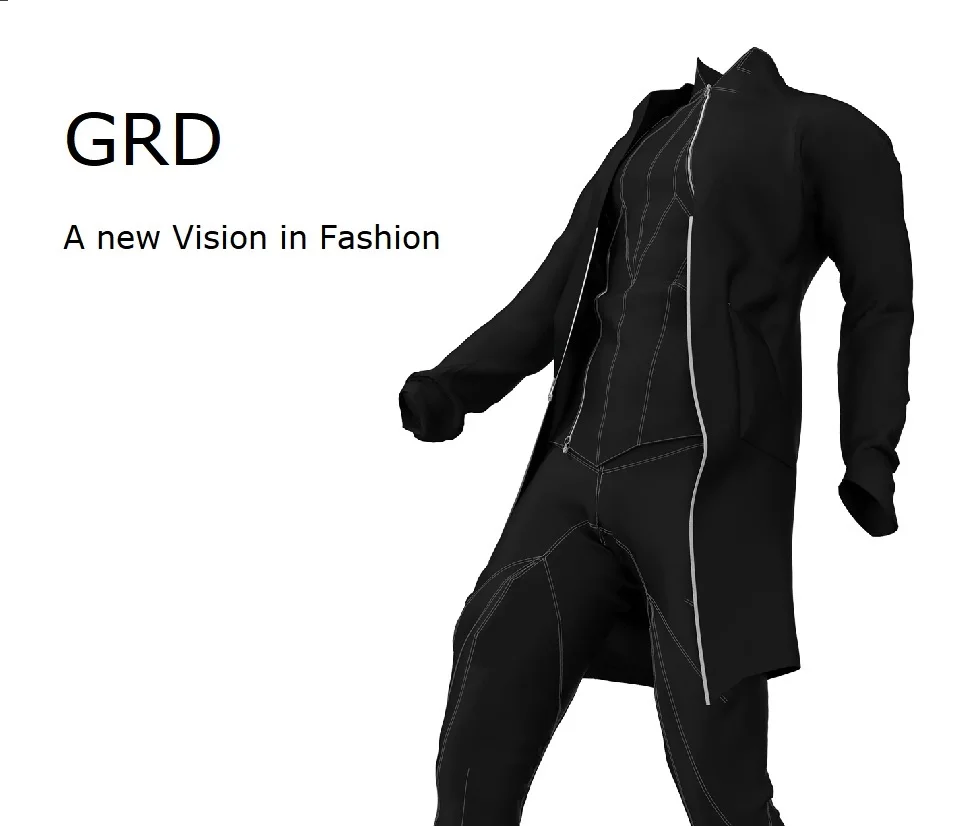

This may have been true in the past but not any more. 3D design (CAD) software products from suppliers including Autodesk , SOLIDWORKS, Rhino 3D and even entry-level products from Clo3D can all be used to create realistic clothing models.

It's been estimated that roughly 70% of the common garments (pants, shirts, jackets, slip dresses, etc...) and shoes consist of basic shapes such as tubes, squares and triangles. The challenge has been in developing simple ways of combining these shapes and simulating realistic fabric behavior.

Whether your approach is starting from scratch or editing existing templates the process has been streamlined and the results are exceptional. Fabric drapes naturally across the virtual mannequins or dress forms. Grading information is included in the model providing a near infinite level of sizing for every aspect of the garment. Pattern graphics can be swapped and rendered to get a feel for the final product in real time.

There's no clean way to convert the 3D design into the 2D Patterns.

This statement is true. This is if you've invested in or are evaluating 3D to 2D flattening software sold by "3D Impostors." The new generation of 3D flattening products like the solutions from ExactFlat are purpose-built to streamline the process. Why start with rough 2D patterns and then go through and tediously add production details on each edge? With true 3D to 2D flattening you simply:

- select the 3D model

- add cut lines where you want seams

- flatten and then optimize the pattern for strain and sag

- add pattern engineering details to every piece in a single step

3D Design and Digital Patterning has proven to be the fastest and most cost effective way to generate production-ready. What's keeping your business from implementing these productivity enhancements?

If you'd like to learn more or gain a better understanding of how Digital design and patterning can work in your business just click on the link below. One of our experts will review your current processes, tools and business improvement goals then let you know how digital automation can help.