Making Custom, Common - The Challenge

Manufacturers face new competitive challenges in the Era of Mass Customization

Many manufacturers believe that they have only two choices when it comes to the types of processes available for the design and fabrication of their products.

Mass Produced. The first, and most common category is mass produced, "cookie cutter" items. This method is used to deliver products quickly with maximum profit margins. Unfortunately, this option tends to place severe limits to the types of personalization available to clients. In addition, in order to achieve the desired “economy of scale” mass-produced goods are typically created in advance of demand. This requires the manufacturers to assume the risks associated with unsold inventory.

Unlike legacy methods, a digital design-to-manufacturing process starts with the 3D CAD model. Models are either created from scratch, edited from templates or 3D scanned. The current generation of 3D CAD software provides designers with nearly limitless freedom to craft the products to their clients specific requirements.

Customized. The second group can be framed as hand crafted, customized products. Personalized products are typically produced using manual methods. This often means a longer lag between purchase and delivery. In addition, while custom goods tend to be sold at premium prices, the incremental labor means that they still generate only nominal profits for the manufacturer.

Digital best practices provide a cost-effective approach for Mass Customization

The move to digital best practices bridges the gaps between risky pre-built inventory, and lower margin personalize products. This mass customization approach allows textile product manufacturers (i.e. fashion, auto interiors, furniture, marine, etc..) to:

1. Create sculpted designs with organic shapes to excite clients

2. Present a virtual prototype of the product for customers to review and purchase

3. Utilize the design and marketing assets immediately in the production process

3D design models serve as the basis for all subsequent stages of the process. For example, renderings of the design are created and used to help clients visualize the final product. In most cases, renderings and material samples replace the use of physical prototypes. This streamlines the process used to gain client purchase commitment.

Digital best practices provide a simple-to-implement way for manufacturers to achieve the competitive benefits of a Mass Customization business model. Using industry proven technologies including 3D CAD, Scanning, and 3D to 2D flattening software, innovative product manufacturers are delivering on the promise of personalized products. These tools enable on-demand production, in unit volumes of one, with delivery time, end user cost and profit margins that rival those of mass-produced goods.

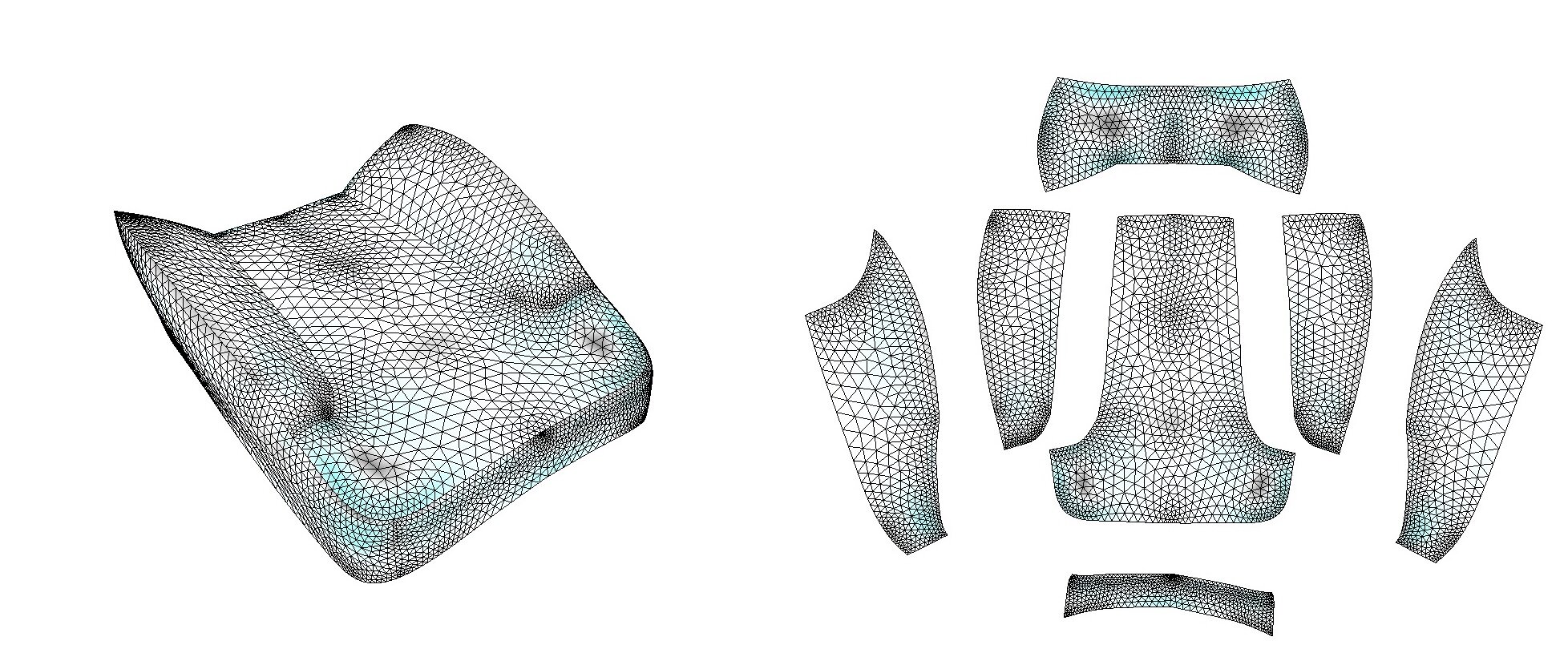

In addition to optimizing the sales and marketing functions, the digital design model is also used directly in the pre-production process. 3D to 2D flattening software like ExactFlat utilizes the design and converts it into production-ready patterns in minutes. This approach can shave days off the product delivery schedule.

Learn More

Learn more about digital best practices. Click on the link to schedule a time with one of our experts. During the session you’ll see how:

- the transition to digital can improve competitiveness and profitability

- the tools fit seamlessly within your existing environment and workflow

Make digital best practices a competitive advantage for your business.

Click on the image and schedule a time to learn more or to leverage our Scan to Pattern promotion to get started right now (Click here)