Enabling Cost-effective use of Composite Materials - Part II

Carbon fiber or woven composites materials are being used in all kinds of engineering applications – anywhere a combination of high strength and very light weight is desired. The barrier to wide spread adoption of these materials can be attributed in a few areas, especially:

Raw materials cost

Production prep time and labor

While increase volume and improvements in consistent materials processing are helping to reduce the raw material costs, the key to addressing the production prep issues lies with the transition to digital design and patterning methods.

Composite Product Manufacturing Processes

The legacy manufacturing process for most composite products follows a standard set of steps:

Pre-Production

Converting the 3D design into 2D patterns

Designing and producing the Mold

Iterating on prototypes to validate the patterns and the molds

Production

Cutting and labeling the raw materials

Fabrication via Autoclave or Resin infusion techniques

Finishing (trim waste, drill holes, etc…) and Assembly processes

The advantage of utilizing a digital design and patterning process is that most if not all of these steps can be automated and accelerated. In this example, we’ll focus on the pre-production steps where the time savings are proven to be as much as a factor of 10.

The use of composite materials, once limited to extremely high-end products only, is estimated to grow dramatically across all types of performance and custom consumer goods. Production labor costs are a key limiting factor and the transition to digital is a proven solution to this challenge.

Converting the 3D design into 2D patterns

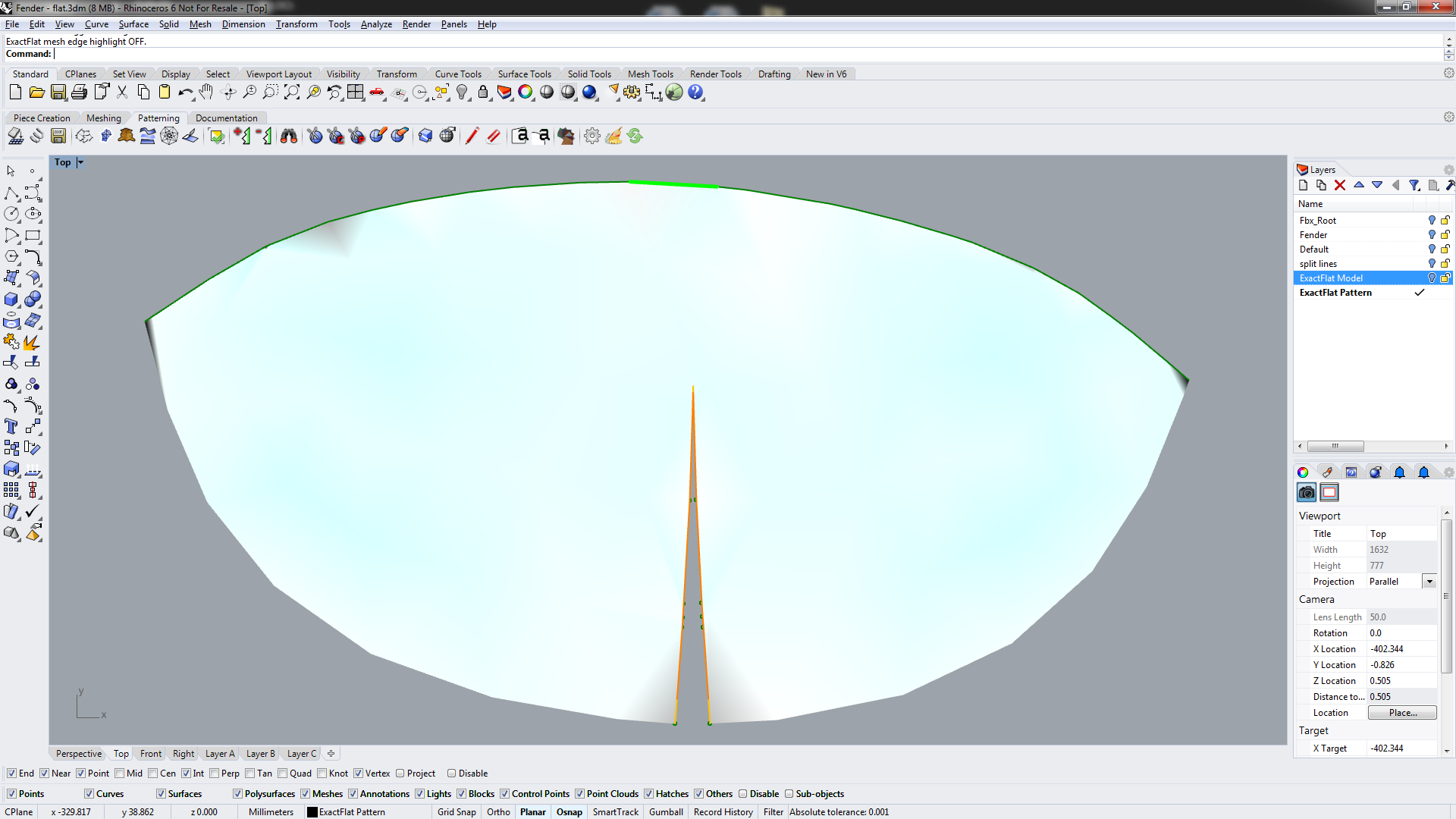

For the motorcycle fender example shown here, the digital process started with the 3D CD model. In this case the original CAD model was provided to the after-market product manufacturing partner. Another viable option for this phase is the use of 3D scanning technology. This process captures the form of an existing product which is then edited into a 3D model.

With the model defined, the designers collaborated directly with the production team to define loading paths for the material layup as well as cuts or seam locations. The 3D model was then flattened into 2D pattern pieces using ExactFlat digital patterning software.

The workflow from 3D design (left) to 2D pattern (right) is completed quickly and simply with ExactFlat.

The Strain analysis tools in ExactFlat enable designers to identify fit issues early in the process….

Validating fit before any material is cut

The 2D patterns were created in a matter of minutes utilizing the material’s specific physical properties and folding behaviors. Then the digital display was used to review the strain at every location in each pattern piece. This is a critical step used to ensure precise manufacturing ability without the need for expensive prototyping.

… and to then edit the pattern or add relief cuts before any material is cut.

Areas of high strain can indicate places with fiber separation or “toeing” can occur. Conversely, areas of low strain suggest places with the material will “bunch up” or sag and eliminate the tension needed to transfer the load properly. It’s a simple process to add strain relief using cuts and darts directly on the pattern and then to repeat the analysis.

Another unique advantage of the digital process is that the mold design and milling can continue simultaneously while the pattern pieces are being analyzed and refined. This is possible because all parts of the production materials are created from the same initial 3D model.

Preparing the patterns for cutting

The last step in this example was to prepare the pattern for cutting. Using Gerber AccuMark we were able to open the 2D pattern then quickly add pattern features such as material salvage, notches and piece labels.

AccuMark recognized any notches or labels we had already created in ExactFlat as well as the grain line information used to orient the pieces for ply layup. In the final stage the ply and piece labelling tools in Gerber software simplified the process of aligning the pieces in the mold after they were cut.

AccuMark, the 2D pattern engineering solution from Gerber Technology works seamlessly with the 3D to 2D flattening software from ExactFlat. This creates an entirely integrated digital environment. Bridging and accelerating the process from 3D design all the way to automated cutting.

Learn More - Webinar May 8, 1:00pm EDT

There are many different reasons for choosing composite materials for aftermarket parts. Some parts offer weight savings while others increase strength or resistance to wear, vibration and impact. Still others protect against excess heat.

The transition to digital processes provides a cost-effective way to design and produce composite products. Join us to learn how to integrate and accelerate the entire digital workflow from 3D CAD to 2D pattern to automated cutter. Webinar participants will gain time-saving insights into the use of ExactFlat and the solutions from Gerber Technology to automate the process.