Can You Increase Productivity With Old Tools and Low Value Activities?

There was a time when it took days and weeks of manual effort to create patterns.

Everyday, pattern makers worked on patterns for standard mass-produced products by drafting with traditional 2D methods.

Commonly used drafting tools for pattern making.

Then changes came:

- Because of product over production, profit began to collapse for mass-produced items.

- Customers and retailer preferences changed, valuing customized products more than generic ones.

- Pattern makers began to disappear. They retired in droves. But, there were not enough new ones to replace them.

Pattern Makers continue to disappear at an alarming rate.

Because of that companies adopted 2D CAD for pattern drafting. But 2D CAD was also slow, and poorly suited for customization.

Because of that profit weakened more. Customization stalled. Pattern makers became even more scarce.

Mass customization will soon be the only way to compete in some industries.

This continued until Tri-D Technologies introduced ExactFlat. ExactFlat creates perfect patterns in minutes. This eliminated the impact of losing 2D pattern makers. Customizing products by the 1000’s became faster and easier than ever before. Companies using ExactFlat strengthened their profit and praised the people involved for their decisions.

ExactFlat: How it’s different? Why it’s Better? What’s in it for you?

Do outdated tools, create up-to-date problems?

All pattern makers want to add value through their work. But 2D CAD is an outdated tool, because it forces pattern makers to use inefficient redundant processes. For example, you must manually associate adjacent pattern pieces, the beginning and end of seam edges, and the alignment of notches. To complete a project, you must repeat this process for every pattern piece and each seam edge. When you make a change, you trigger a cascade of manual edits similar to “chasing your tail, until you tire yourself out.” Pattern makers are busy. The results they achieve are valued, but drafting patterns with an outdated tool like 2D CAD is manual and slow.

All 2D CAD is slow.

Get rid of low-value work. Make high-value patterns in minutes.

ExactFlat is better because it automates low value repetitive work like creating pattern associations. It is like that because we start with 3D designs. We index and maintain associations from the 3D design, and apply them to 2D patterning. It is logical. This helps you make your patterns in minutes so your business becomes more agile.

ExactFlat creates patterns that fit perfectly.

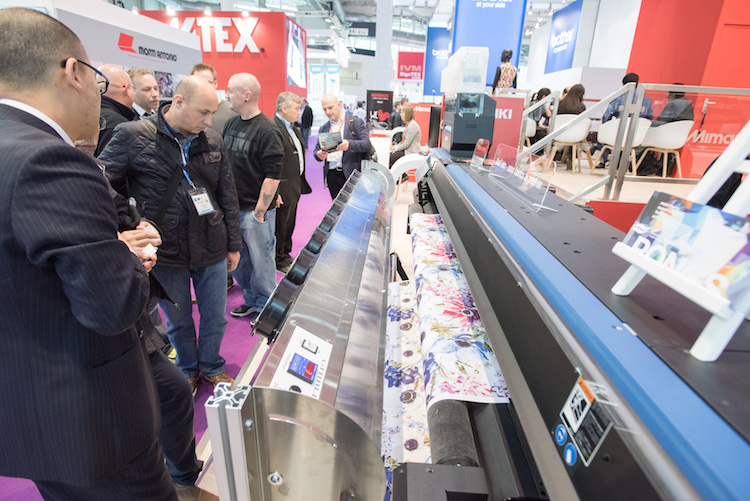

Even non-experts can create patterns that fit perfectly. Why? We created a digital fabric that is just like real fabric. This helps automate the precise adjustments from 3D shapes into perfect 2D patterns. It works on any surface, and any material type. It even works with graphics and textures applied to 3D surfaces. You can get more value out of your digital textile printer because ExactFlat can create flat patterns with images perfectly applied and ready to print.

ExactFlat works with any modern cutter and any digital textile printer.

Easily print and cut your files. You can do this on any modern textile printers and cuters because a variety of file formats are supported. For example: cutter formats like DXF. Printer formats like .Jpg, .Png, and .Tiff for printing on textiles, and .PDF format with both graphic and cut information

The return of your agile business is just the beginning.

If you have been drafting your patterns with 2D CAD, when you switch to ExactFlat you will get your agile business back. Better agility to be responsive to customers. Better agility for pursuing new opportunities. Better agility for becoming an efficient boss over your competitors. Why use ExactFlat? Because with it, your pattern makers will make great products your customers love. This will help you strengthen your profit and bask in the praise of good decision making.